In real life, in order to get the same workpiece, mass production is also required. At this time, the mold is used. In order to achieve fast and stable continuous production, there are automatic molds, or continuous molds.

The metal stamping self-service punching die refers to a cold punching die that uses a belt-shaped punching material in a single punching process and finishes multiple punching processes on the mold at the same time. Each punching is completed once and the data belt moves at a fixed distance. Product processing until the end of the product.

The focus of continuous molds is on the material strip because the material strip is the center of the entire mold. In the meantime, the design of the data belt is mainly to grasp the design idea, knowing that the belt is composed of several parts, such as: data points, splitting orientation, bending process, etc. The data band is a practical demonstration of the product's transition from sheet metal to product. Therefore, the data strip is very important.

1 The stamped part does not completely fall off but can be removed by hand

The metal stamping mold product is engaged with the strip to leave the mold, and the punch product is engaged with the strip. Unlike the terminal, the stamped part can be separated from the strip by hand.

2Able to fall directly

Flush the product directly at the end of the stamping die and separate the stamped product from the strip.

3Stamped parts are still on the tape

The stamped product is attached to the tape and the molds are put together. Punching products and information tape are connected together. There is a data collector behind the stamping die, which is used to connect the stamped product with the data tape.

The above is the knowledge of automatic touch of metal stamping. After reading here, I trust that we have a better understanding of the knowledge of automatic touch.

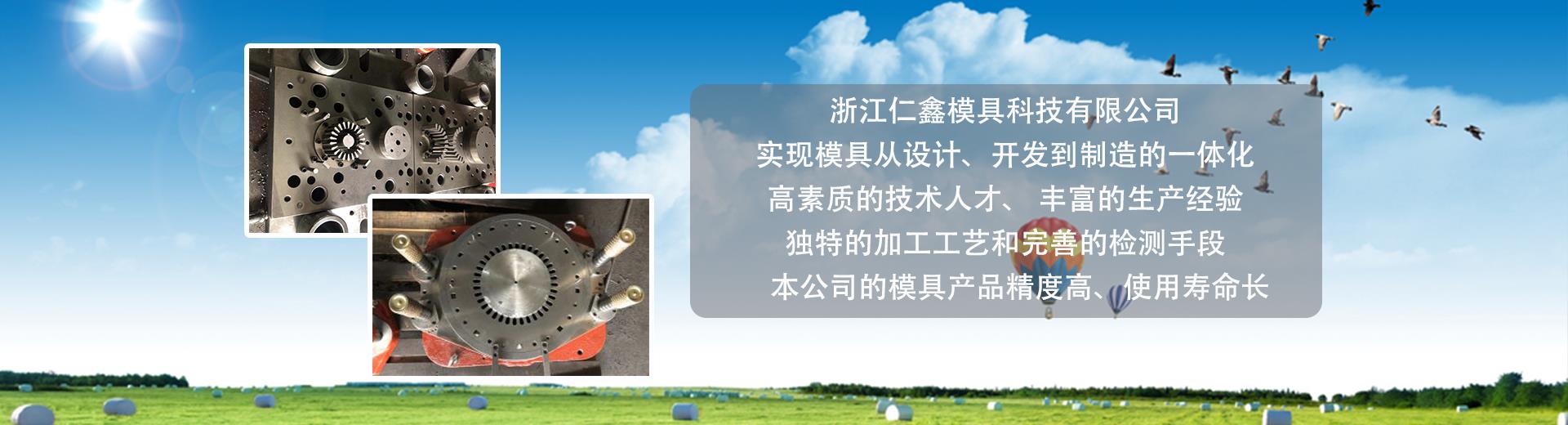

The company expanded its production scale to build a new plant in Quzhou, covering an area of more than 4,000 square meters. In recent years, while continuously introducing high-quality technical personnel, it has also introduced dozens of high-precision, sophisticated CNC machining stator molds and gantry floods Grinder rotor die and slow-moving equipment compound die, equipped with excellent and unique computer network system design and processing software

Previous: Introduction of blanking die

Related News

- High-voltage motor punching die operation specification

- What are the components of a simple stamping blanking mold?

- Blanking die process and principle

- Using method of rotor casting aluminum mold

- Structural factors affecting composite molds

- Possible problems with rotor molds

- Precautions in the use of self-service die

- Characteristics of stator mold

- Introduction of blanking die

- Attentions in the design of fixed-rotor tooling fixtures

- Precautions for the use of stator embossing molds