(1) There must be one (or several) convex and concave molds in the composite mold, and the convex and concave molds are the central parts of the composite mold. The precision of punching parts is higher than that of single process die punching. The precision of ordinary punching parts can reach IT10 ~ IT11.

(2) The parts punched out by the compound die are pushed out from the die mouth, and the parts are relatively flat.

(3) The punching part of the compound die is more complicated, and various mechanisms are arranged around the working part of the die, so its closing height is often high, and special attention should be paid to the design.

(4) The cost of the compound die is relatively high, the manufacturing cycle is long, and it is generally suitable to consume a large number of stamping parts.

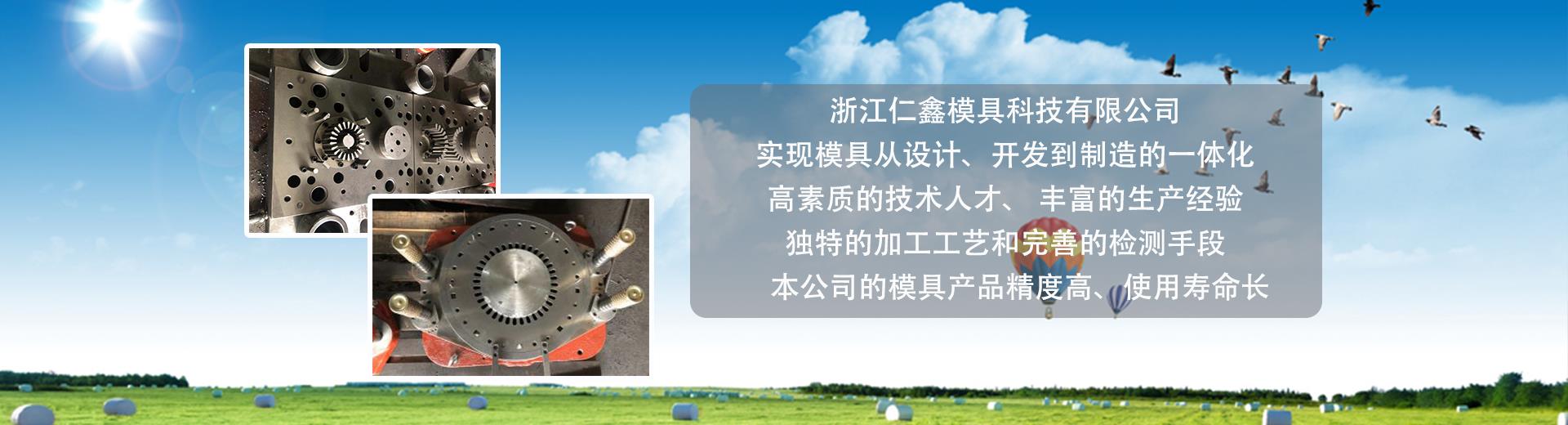

(5) When designing the composite mold, ensure the strength of the convex and concave molds, and pay special attention to the small wall thickness of the convex and concave molds. In order to increase the strength of the male and female die and reduce the expansion force of the waste material in the hole, the method of increasing the wall thickness below the effective cutting edge of the male and female die and ejecting the waste material in the opposite direction can be adopted, as shown in the right figure.

(6) There are many ways to install the pusher of the compound mold. When designing, pay attention to the amount of activity of the board and the push block should be sufficient, and the amount of activity of the two should be different. The push block of the mold should open the die 0.2 ~ 0.5 mm.

(7) There are many ways to apply the mold handle in the compound mold, such as press type, screw-in type, flange type, floating type, etc. can be selected. It should be ensured that the mold handle fits well into the mold base and has sufficient stability. , Can not reduce the strength of the mold handle due to the setting of the ejection mechanism, or increase the mold closing height too large.

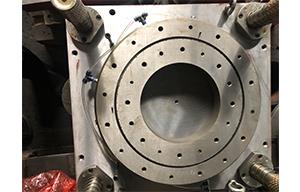

Zhejiang Renxin Mould Technology Co., Ltd. has maintained rapid development since the establishment of Taizhou Luqiao Renxin Company in 2003, and its business scope has expanded rapidly. Is a professional stator mold, rotor mold, stator embossing mold production and development enterprises. The company expanded its production scale to build a new plant in Quzhou, covering an area of more than 4,000 square meters. In recent years, while continuously introducing high-quality technical personnel, it has also introduced dozens of high-precision, sophisticated CNC machining stator molds and gantry floods. The grinder rotor mold and the compound mold of the slow-walking equipment are equipped with excellent and unique computer network system design and processing software, which realizes the integration of mold from design, development to manufacturing. High-quality technical personnel, advanced processing equipment, rich production experience, unique processing technology and perfect testing methods ensure that the company's mold products have high precision and long service life.

Previous: No Information

Related Industry Knowledge

- Precautions for the use of stator embossing molds

- Structural composition of blanking die

- Key points of planning for composite molds

- Advantages and disadvantages of compound mold

- Application of fixed rotor fixture

- What is the difference between continuous mode and composite mode?

- Classification of high voltage motor punching die

- Application of Rotor Casting Aluminum Mold

- Selection of generator punch die

- What factors determine the quality of the stator mold?