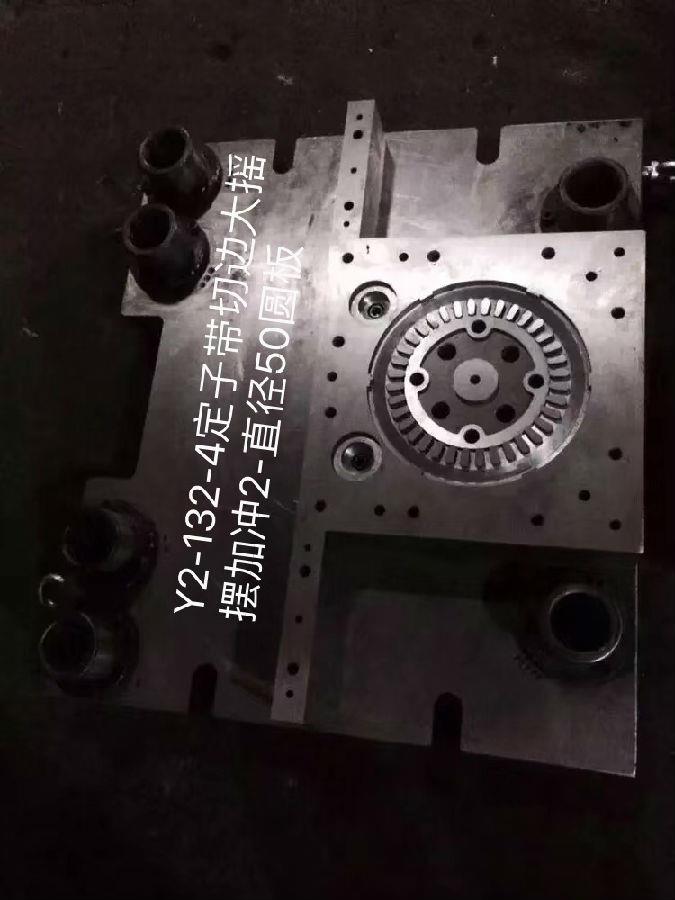

The first is the planning process of the cast iron parts of the stator . When planning, in addition to determining the shape and size of the cast iron parts according to the working conditions and metal data properties, the rationality of the planning must be considered from the perspective of casting alloy and casting process characteristics, that is, obvious scale effects and condensation, Shrinkage, stress and other problems to prevent or reduce the occurrence of defects such as segregation, deformation and cracking of cast iron components.

The second is to have a reasonable casting process. That is, according to the structure, weight, and size of the cast iron, the characteristics of the casting alloy and the production conditions, the appropriate parting surface, shape, and core making method are selected, and the casting ribs, cold iron, riser, and pouring system are reasonably set. In order to ensure the quality of stator iron castings.

The third is the quality of the original materials for casting. The quality of materials such as metal charge, refractory materials, fuels, fluxes, modifiers, and foundry sands, molding sand binders, coatings and other materials is not up to standard, which will cause defects such as pores, pinholes, slag inclusions, and sand sticking in cast iron parts, affecting cast iron parts Appearance quality and internal quality will make cast iron parts invalid when severe. The fourth is the process operation. It is necessary to formulate a reasonable process operation procedure, improve the skill level of workers, and make the process procedure correctly implemented.

During the production, the quality of the castings must be controlled and inspected. First of all, it is necessary to formulate the technical rules and technical conditions from the original materials and auxiliary materials to the control and inspection of each detailed product. Each process is strictly controlled and inspected in accordance with the process code and skill conditions. Check the quality of the product castings. Equipped with reasonable testing methods and suitable testing personnel. Generally speaking, for the appearance quality of professional cast iron parts, the surface roughness of the casting can be judged by comparing the samples; the fine cracks on the surface can be inspected by the coloring method and the magnetic particle method.

Previous: Design points of compound mold

Related Industry Knowledge

- Precautions for the use of stator embossing molds

- Structural composition of blanking die

- Key points of planning for composite molds

- Advantages and disadvantages of compound mold

- Application of fixed rotor fixture

- What is the difference between continuous mode and composite mode?

- Classification of high voltage motor punching die

- Application of Rotor Casting Aluminum Mold

- Selection of generator punch die

- Design points of compound mold