Generator punching die materials are very extensive. Depending on the output of the casting, that is, the number of times the casting mold is used, wood, plastic, aluminum alloy, cast iron, and steel can be selected.

Wooden molds are still widely used in manual molding or single-piece small batch production, but with the increasingly strict environmental protection requirements, the use of wood will be increasingly restricted, and will be replaced by solid casting. Solid casting uses foam plastic sheet as the material, cuts and bonds to form the appearance, and then casts it into a casting. Compared with the use of wooden molds, this method not only saves wood, but also makes castings have higher dimensional accuracy and better appearance roughness. The use of plastic molds is on the rise, especially the availability of processable plastics to the market and the life of plastic molds With the advancement of several numbers, the use of plastic molds has become increasingly widespread.

Because of its light weight and high dimensional accuracy, aluminum alloy molds are still widely used. However, there has been a recent reduction in use, and some scales have been replaced by plastic molds (when the batches of castings are smaller) or cast iron molds (when the batches of castings are larger).

The cast iron mold is still the choice for large-scale casting production and is used in large quantities. It has the advantages of high strength, high hardness, wear resistance, good workability, low cost, and long service life. In recent years, due to the advancement of casting level, more and more appearances, mold base plates, profile plates and frames have been made of ductile iron or low rare-earth alloy gray cast iron with higher strength and wear resistance. Better vermicular graphite cast iron is also used as the core box material.

In the past, steel was mainly used for standard parts, wear-resistant inserts or linings on casting molds, and was less used for manufacturing casting mold bodies, because the service life of carbon steel is not higher than that of ductile iron or low-alloy gray iron, and the price of alloy steel And very expensive. However, with the development of mold processing technology and the improvement of the requirements for the scale stability of casting molds, mold steel and chromium-molybdenum alloy steel are also used to manufacture casting molds. The appearance and core box body of a car cylinder mold introduced from France by a factory are made of 40CMD8 (French specification) chrome-molybdenum steel. The service life is 1 million times of appearance and 500,000 times of core box. In addition, more and more steels have been used for manufacturing tooling parts such as mold base plates and core box frames.

Related Industry Knowledge

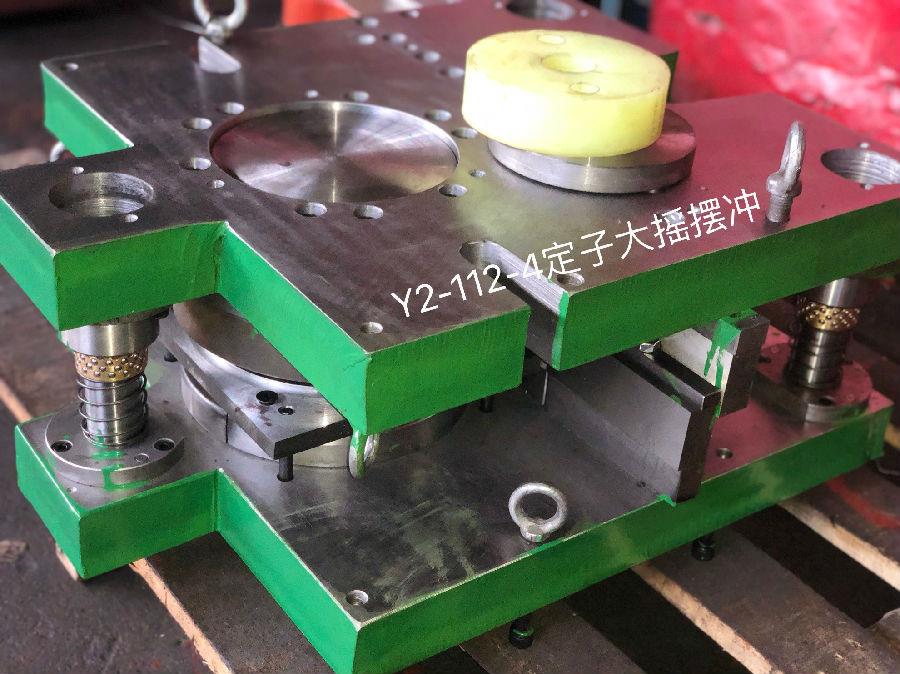

- Precautions for the use of stator embossing molds

- Structural composition of blanking die

- Key points of planning for composite molds

- Advantages and disadvantages of compound mold

- Application of fixed rotor fixture

- What is the difference between continuous mode and composite mode?

- Classification of high voltage motor punching die

- Application of Rotor Casting Aluminum Mold

- What factors determine the quality of the stator mold?

- Design points of compound mold