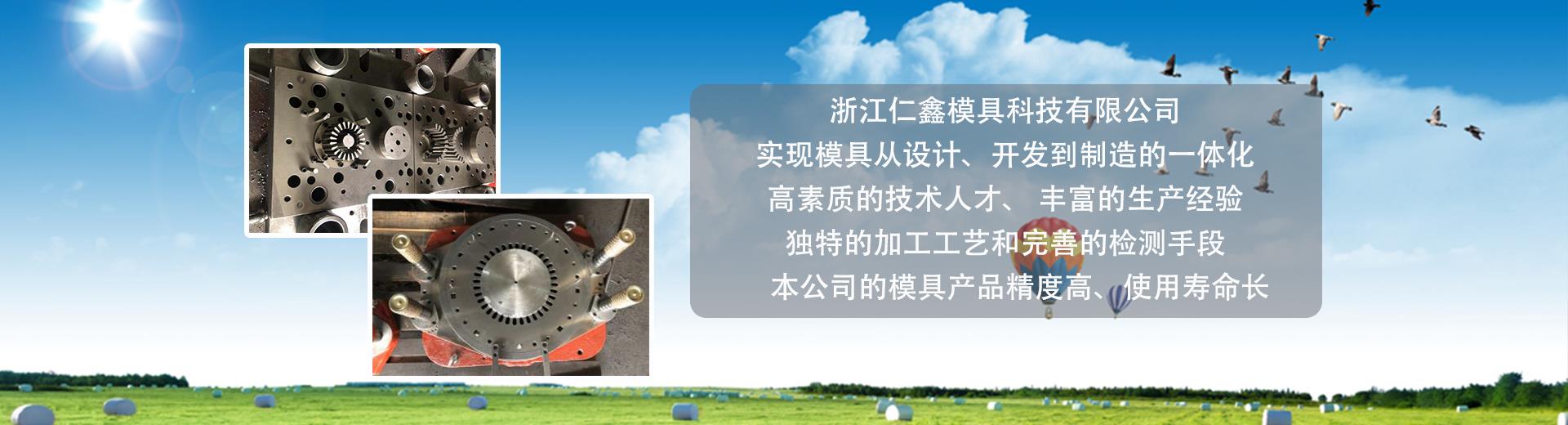

Cast aluminum mould

Casting aluminum molds: This process is to punch the rotor blades through a die-casting aluminum machine to make the rotor into finished rotors. The motor motor punching molds are all processed by CNC lathes, and the machining center is automatically chamfered. The wire-shaped upper and lower profiled aluminum wind blade grooves are processed and formed at one time, and then quenched and tempered, and then light-nitrided. It is an essential process link for rotor blades. More reasonable.

The working principle of pressure cast aluminum is to inject molten metal aluminum into the cavity with pressure, and then cool and solidify into a casting. Its characteristics are: (1) throughout the die-casting process, pressure plays a major role. (2) During die casting, during the high-speed punching process of the metal liquid, if the gas in the cavity is too late to be exhausted, it will be drawn into the metal to generate air holes. (3) Since the metal filling process is performed under pressure, the rotor core can be die-cast in the cold state. (4) High production efficiency, easy to realize mechanization and automation, which can reduce labor intensity.